Oplev blid og effektiv PMS støtte med Linnuo Pharmaceuticals gummiformel. Vores PMS gummies er ekspertformuleret til at give målrettet lindring fra ubehagene ved præmenstruelt syndrom, herunder kramper, oppustethed og irritabilitet. Lavet med milde ingredienser og fri for kunstige tilsætningsstoffer, tilbyder vores gummies en sikker og naturlig måde at støtte din krop under PMS. Stol på Linnuo Pharmaceuticals gummiformel til at give den støtte, du har brug for under din menstruationscyklus.

Linnuo Pharmaceuticals PMS Gummies blev lavet specifikt til holistisk pleje i hver fase af den kvindelige cyklus. Disse gummies indeholder mange vitaminer og mineraler, som menes at være nødvendige for god mental sundhed, mindske hævelse over hele kroppen og skabe fred inden i sig selv. Folinsyre og zink hjælper også med at balancere hormoner, hvilket kan holde kvinder til at føle sig bedst, mens de har deres menstruation.

Linnuo Pharmaceuticals PMS Gummies: Sund hud og godt hår Linnuo Pharmaceuticals PMS Gummies er designet til at hjælpe med hud- og hårproblemer forårsaget af præmenstruelt syndrom. Disse tyggegummier indeholder biotin samt vitamin E, som forbedrer tilstanden af huden og håret. De har også antiinflammatoriske komponenter, der kan minimere akne eller andre ansigtsskader, hvilket efterlader en strålende udseende.

PMS gummies fra Linnuo Pharmaceutical kan hjælpe med trang, som er et typisk problem i den præmenstruelle periode. De er fremstillet med ingredienser, der kan hjælpe med at kontrollere blodsukkerniveauet samt mindske sultfornemmelser; derfor er disse slik ikke kun velsmagende, men også gode for helbredet, da de fungerer som erstatninger for sukkerholdige snacks. Kvinder, der ønsker at opfylde deres ernæringsmæssige behov, mens de oplever PMS, elsker det faktum, at dette produkt indeholder naturlige smagsstoffer og har en behagelig tekstur.

Hver Gummy med Bekvemmelighed og Velvære. Hvis du er en travl kvinde, bør du overveje at bruge Linnuo Pharmaceuticals PMS Gummies på grund af deres bekvemmelighed. Du kan nemt tage disse gummies med dig, og de vil ikke være noget besvær. Dette skyldes, at de er designet til at være lette, så det ikke bliver svært for nogen, der har brug for dem under deres rejser, at tage dem med. Derfor, hvis du har brug for ernæring, mens du altid er på farten, vil dette fungere godt for dig. For at være effektiv til at give lindring fra præmenstruelt syndrom (PMS), indeholder den alle nødvendige næringsstoffer i en passende dosis, som hjælper med at opretholde hormonel balance gennem en kvindes menstruationscyklus. Det bliver ikke bedre end vores PMS Gummies, når det kommer til at holde sig i form og forblive sund!

Grundlagt i 2009 som et datterselskab af Zhongying Group, er Zhengzhou Linnuo Pharmaceutical Co., Ltd. vokset til en omfattende industrikædevirksomhed, der specialiserer sig i videnskabelig forskning, fremstilling, markedsføring og produktion. Fokuseret på at levere OEM/ODM-tjenester til B-slutkunder, har det professionelle produktionslinjer til forskellige produkter skræddersyet til vægtstyring, sportsnæring og nærende måltider. Med en mission om at tjene menneskers sundhed og et engagement i tro og ansvar, sigter virksomheden mod at forbinde millioner til sundhed gennem kvalitetsprodukter. Ved at opretholde en oprigtig tro, en streng holdning og en innovativ ånd, stræber den efter at levere differentierede, konkurrencedygtige produkter og ser frem til samarbejdspartnerskaber for at opnå strålende resultater.

Linnuo Pharmaceutical udmærker sig i branchen på grund af sin omfattende ekspertise inden for forskning og udvikling. Vores dedikerede FoU-team er forpligtet til at skabe innovative og effektive kosttilskud. Dette fokus på avanceret forskning sikrer, at vores produkter ikke blot er sikre, men også optimeret til maksimal effektivitet. Ved løbende at investere i forskning og udvikling er vi i stand til at holde os foran markedstrendene og levere overlegne produkter, der opfylder vores kunders skiftende behov.

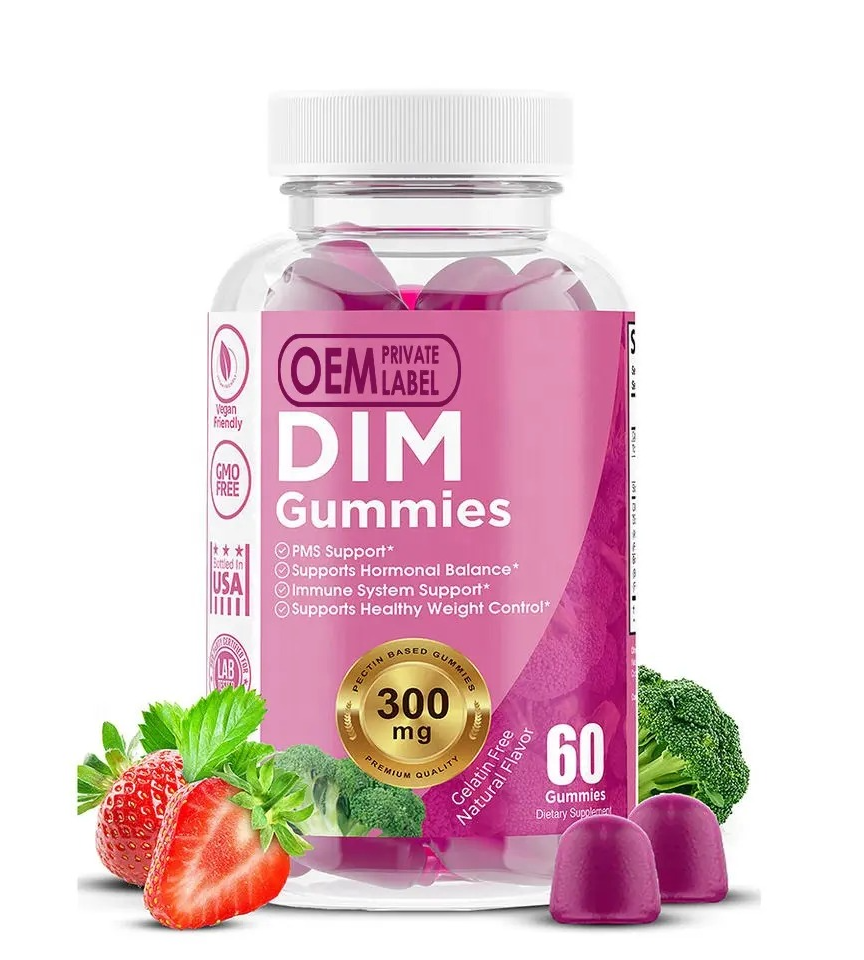

Kvalitet og sikkerhed er kernen i alt, hvad vi gør hos Linnuo Pharmaceutical. Vores produktionsprocesser følger strenge kvalitetsstandarder, hvilket sikrer, at hver batch af gummies og kapsler opfylder de højeste industri-standarder. Vi bruger kun førsteklasses, ikke-GMO ingredienser fra betroede leverandører, og vores produkter gennemgår strenge tests for at garantere deres renhed og styrke. Denne urokkelige forpligtelse til at sikre kvalitet sikrer, at vores kunder får sikre, pålidelige og effektive kosttilskud.

Linnuo Pharmaceutical tilbyder meget tilpasningsmæssige løsninger til at imødekomme vores kunders unikke behov. Uanset om du søger efter specifikke formuleringer, brugerdefinerede smagsstoffer eller skræddersyede emballagealternativer, kan vi levere løsninger, der passer til dit brand og markedets krav. Vores fleksibilitet og engagement i kundetilfredshed gør os til en foretrukken partner for virksomheder, der ønsker at tilbyde kvalitets- og differentierede kosttilskud.

Vi er dedikeret til bæredygtighed og etiske forretningsmetoder hos Linnuo Pharmaceutical. Vores produktionsprocesser er designet til at minimere miljøpåvirkningen, og vi prioriterer at indkøbe ingredienser fra bæredygtige og etiske leverandører. Ved at vælge vores produkter støtter du en virksomhed, der værdsætter miljøforsyning og socialt ansvar. Denne forpligtelse til bæredygtighed er ikke kun til gavn for planeten, men giver også genklang hos forbrugerne, der i stigende grad træffer miljøbevidste købsbeslutninger.

PMS-gummier er en type sundhedssuppler, der er specielt udformet til at hjælpe med at alivere symptomer forbundet med præmenstruel syndrom (PMS).

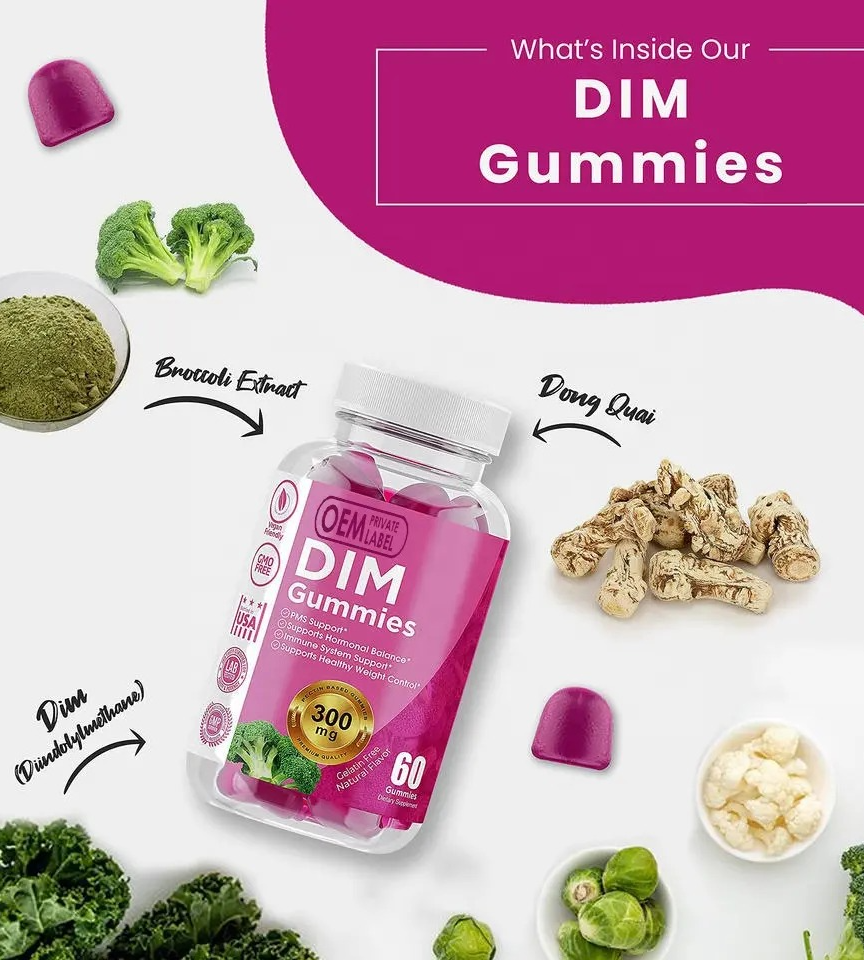

PMS-gummier indeholder ofte ingredienser der kan hjælpe med at regulere hormonubalancer og understøtte det generelle velbefindende under menstruationscyklussen.

Selv om resultaterne kan variere fra person til person, er PMS-gummierne fremstillet med ingredienser der traditionelt er blevet brugt til at lindre almindelige PMS-symptomer.

PMS-gummier kan potentielvis hjælpe med symptomer som opblåst肚, mood swings, træthed og menstruelle krampeter.

Den tid det tager at få virkningerne af PMS- gummi kan variere fra person til person. Det anbefales ofte at tage dem konsekvent i nogle få menstruationscyklusser for at vurdere eventuelle fordele.